Contents

1.1 Summary of the context and overall objectives of the project

1.2 Work performed and progress beyond state of the art

Innovative chase aircraft acoustic in-flight measurement methodology

Improved methods for acoustic measurements in wind tunnel

Representative engine acoustic liners at wind tunnel scale

Composite fan blade design for wind tunnel models

Numerical extrapolation of wind tunnel data

Numerical representation of buzz saw noise and acoustic liners

New generation of rotating balances

Dynamic data acquisition system

1.3 Expected potential impact

Expected impact

1 Summary for publication

1.1 Summary of the context and overall objectives of the project

Novel engine technology can deliver a step change in the reduction of fuel consumption and noise. The development of innovative propulsion concepts and their integration in large transport aircraft is therefore a key contributor to achieve the environmental targets for aviation as set in FlightPath2050.

The leading European aircraft and aero-engine industry proceeds in Clean Sky 2 with the development of candidate low fuel burn propulsion concepts following both evolutionary and more revolutionary paths:

- The Ultra High Bypass Ratio turbofan (UHBR)

- The Open-Rotor

Numerical analysis and wind tunnel test campaigns are indispensable for the development of future aircraft that will be designed specifically around such novel propulsion systems, including the preparation of flight test.

Focused towards these Clean Sky 2 activities, the overall PropMat project objective is to make a distinctive contribution to the technology maturation of the novel propulsion concepts with:

- Innovative numerical and experimental methods and tools as needed for aerodynamic &-acoustic characterisation,

- Analyses and experimental results for the novel propulsion concepts for large transport aircraft (aircraft concepts, wind tunnel models, flight demonstrators and/or product aircraft)

1.2 Work performed and progress beyond state of the art

Innovative chase aircraft acoustic in-flight measurement methodology

Work performed:

PropMat investigated an innovative chase aircraft acoustic in-flight measurement methodology through an experimental test campaign in which NLR’s Citation aircraft has been measuring the noise of a propeller aircraft. The feasibility was demonstrated of providing accurate acoustic in-flight measurements in all directions and at various distances from the flying demonstrator of an innovative engine configuration, in various operational conditions.

Progress beyond state of the art

For acoustic in-flight measurements the state of the art is to assess the take-off and approach acoustic characteristics of an aircraft using ground instrumentation (side-line and fly-over noise microphones). In the NINHA EU project microphones were flush mounted on a A320 (chase aircraft) front fuselage, prepared and operated by Airbus, to measure the noise coming from above (A400M). PropMat’s use of microphones mounted on a nose boom, in an area not impacted by engine noise, enables a much wider angular measurement range (including for noise coming from below). This meets for the first time the angular range that Airbus required for Open-Rotor measurements.

During the flight test of the innovative chase aircraft acoustic in-flight measurement method

During the flight test of the innovative chase aircraft acoustic in-flight measurement method

View from NLR’s Citation research aircraft on the propeller aircraft of which the noise is measured

View from NLR’s Citation research aircraft on the propeller aircraft of which the noise is measured

NLR’s Citation research aircraft equipped with nose boom with acoustic sensors

NLR’s Citation research aircraft equipped with nose boom with acoustic sensors

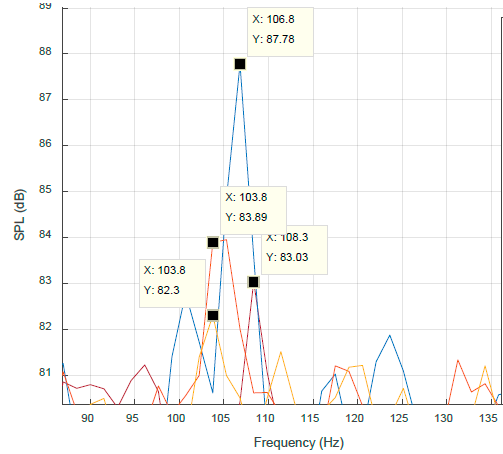

Detailed analysis of propeller noise measured during flight test of PropMat’s innovative chase aircraft acoustic in-flight measurement methodology: acoustic data during overtake at different distances (coloured lines) between the propeller aircraft and the chase aircraft

Improved methods for acoustic measurements in wind tunnel

Work performed:

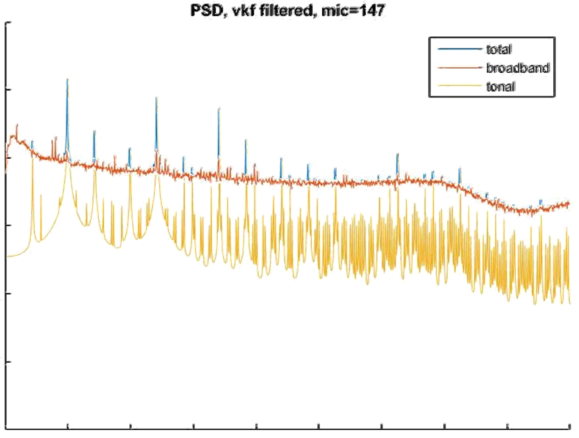

A data processing method has been developed to separate tones and broadband noise in wind tunnel experimental acoustic data for a CROR configuration. The method has been validated on multiple data sets from two different wind tunnel tests. In addition, a method has been developed and verified to assess the acoustic modes in the inlet of a UHBR with a sensor array, including guidelines for its design.

Progress beyond state of the art

For separation of tonal and broadband noise in wind tunnel experimental acoustic data the state of the art is to couple the data averaging to the 1P signal of the rotor. This is no longer possible for CROR engines. PropMat provides the data processing method to separate the tonal and broadband noise for understanding the noise-generation mechanism of CROR engines based on acoustic wind tunnel data.

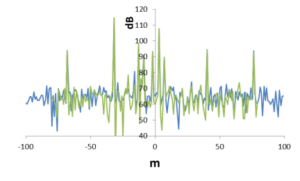

Validation of wind tunnel data processing method for separation of broadband and tonal noise

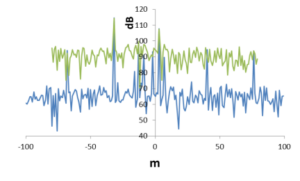

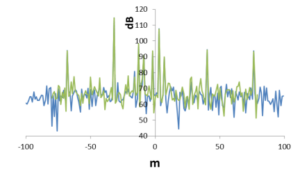

To understand the generation and propagation of noise inside the nacelle of a UHBR it is necessary to decompose the acoustic field into azimuthal modes. A study has been carried out on different concepts of instrumentation and mode detection methods. Recommendations have been derived for the design of the instrumentation and the choice of mode detection algorithm.

|

|

|

|

DFT |

OMP |

DEC |

Verification of three candidate methods for acoustic mode detection (green) in the inlet of a UHBR against a reference spectrum (blue). DFT = discrete Fourier transform, DEC = deconvolution, OMP = orthogonal matching pursuit. Here DFT performs poorly; both OMP and DEC are adequate.

Representative engine acoustic liners at wind tunnel scale

Work performed:

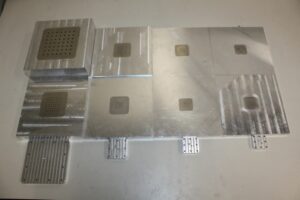

The possibilities to design and manufacture scaled acoustic liners for wind tunnel models have been investigated. First a design approach for geometrically scaled liners has been developed, taking into account performance requirements, manufacturing, and testing constraints. The design approach was verified on eight samples. For further improvement, parameters of the scaled liners have been tuned.

Progress beyond state of the art:

Acoustic testing in on scaled wind tunnel models requires also the appropriate scaling of acoustic liners, if present. A design approach has been developed, the first step of which consists of geometrical scaling. This has been applied to a number of samples which have been tested in an impedance tube. Further tuning steps have been prepared.

Manufactured geometrically scaled liners for in-situ impedance testing in flow duct facility (scale 1:0.5 – 1:4.0, uninstrumented)

Composite fan blade design for wind tunnel models

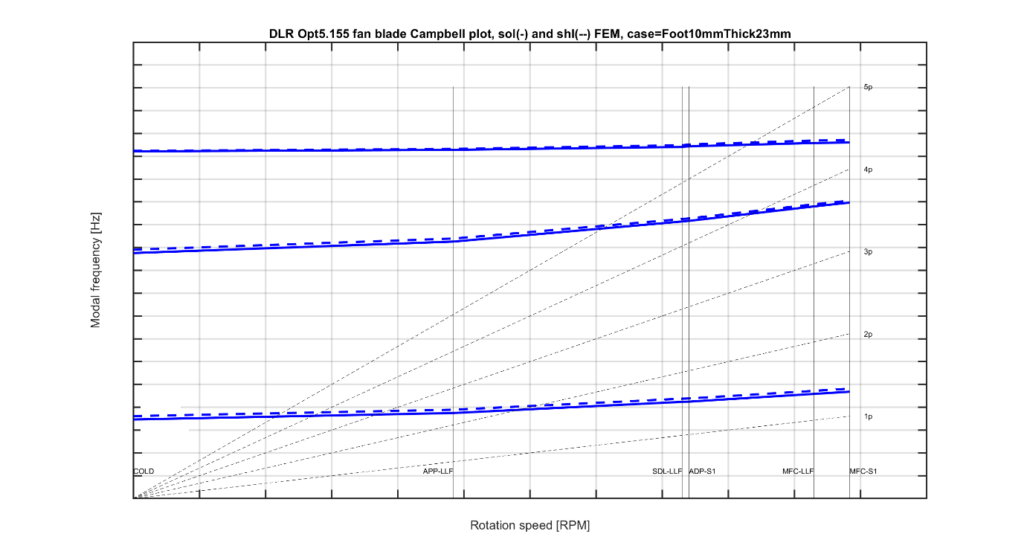

Work performed:

Design and advanced finite element modelling methods were developed to extend the aeroshape of the fan blade at wind tunnel scale with foot and fixation and to define the internal structure of the full composite fan blade, including ply lay-up and orientation, for accurate manufacturing. Design and modelling methods were verified on coupon and element levels. Methods were initially verified against the fan blade aeroshape from the EU ASPIRE project and later applied on the initial aeroshape for the fan blades for an UHBR wind tunnel test, as a contribution to the fan blade Preliminary Design Review in LPA.

Progress beyond state of the art:

Regarding fan blade design the state of the art is to compute a steady-state shape pre-deformation correction to the metallic turbofan fan blade moulds. For many novel engine concepts the inflow is distorted and light-weight composite fan blades are used. State-of-the-art methods may be insufficient to fully cover the distortion effect. In addition, composite complicates the structural modelling. PropMat has set steps to model such composite fan blades at wind tunnel scale more accurately on the way to the final target of accuracy.

Tensile test of element representative for composite fan blade with foot of a UHBR engine at wind tunnel scale

Campbell diagram for fan blade external aeroshape, extended by PropMat with blade foot and internal composites structure, showing modal response against rotation speed. The first 3 eigenfrequencies predicted by the shell FE (dashed line) and solid FE (solid line) models are shown.

Numerical extrapolation of wind tunnel data

Work performed:

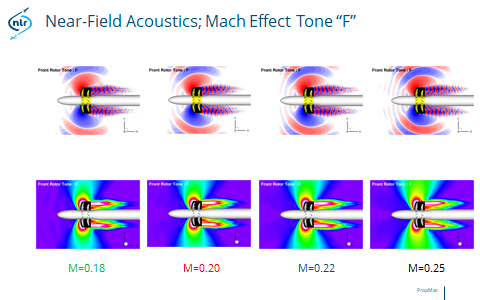

Wind tunnel experimental data in the DNW-LLF data base for the CROR configuration from Clean Sky 1 were extrapolated. Numerical extrapolation techniques were validated with the DNW-LLF experimental data. Next the DNW-LLF experimental data base was extrapolated to higher Mach numbers for representativeness at aircraft take-off.

Progress with respect to state-of-the-art:

Regarding the wind tunnel experimental database from Clean Sky1, PropMat has extrapolated the database to a Mach number that could not have been tested. PropMat has also validated the extrapolation methods.

Extrapolation of DNW-LLF acoustic results to higher Mach numbers

Numerical representation of buzz saw noise and acoustic liners

Work performed:

Numerical methods were developed to represent both buzz saw noise (dominant sound source at take-off) and the behaviour of acoustic liners (to reduce engine noise) in the intakes of turbofans in CFD-based simulations. The method for acoustic liners was validated through an experiment in a liner test facility. Realistic sounds were obtained when simulating buzz saw noise in a UHBR engine. The effectiveness of the acoustic liners in attenuating the buzz saw sound waves could be quantified.

Progress with respect to state-of-the-art:

The novel integration of acoustic liners in CFD computations allows to better predict their contribution to community noise reduction, which previously could not be done. Combined with novel numerical representation of buzz saw noise, this is an essential enabler for industry to master (short-inlet) UHBR engines community and cabin noise during approach.

New generation of rotating balances

Work performed:

A new generation of rotating balances was developed for force and moments measurements in wind tunnel models of engines. A defect free topology-optimised balance demonstrator was additively manufactured.

Progress with respect to state-of-the-art:

The novel manufacturing method for rotating balances gives opportunities for increased measurement accuracy, while reducing manufacturing cost and time. The new generation of rotating balances thus obtained enables better predictions about the full scale next-generation engine design.

Topology optimized rotating balance design developed at NLR

Dynamic data acquisition system

Work performed:

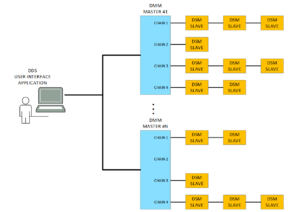

A concept for a data acquisition system was developed for a large number of dynamic sensors (microphones and pressure sensors) in the limited space of a UHBR wind tunnel model. A technology demonstrator has been built and its functionality has been validated.

Progress with respect to state-of-the-art:

The demonstrated concept of the dynamic data acquisition system enables significantly more aerodynamic and aero-acoustic sensors to be used than presently. With the ever increasing needs for such measurements when advancing engines, this will be the dynamic data acquisition system for the next generation wind tunnel models.

Generic concept of PropMat DynDAS technology demonstrator

Master module of DynDAS demonstrator (on the left) with a single chain, consisting of two slave modules (on the right), of which one is packaged.

1.3 Expected potential impact

Expected impact

On the economic and environmental level PropMat’s results obtained so far are already key steps to reduce the development risk of emission-friendly aircraft with non-conventional acoustic behaviour. It is essential to have a deep understanding of and to master the behaviour of the innovative engines at all aircraft models (concept, wind tunnel model, flight test demonstrator, product aircraft) by numerical and experimental means.

On economic and socio-economic level PropMat therefore enables a technology leap by the European industry in the face of emerging competitors for large passenger aircraft. Investigations on emission-friendly aircraft such as Open Rotor, UHBR, and BLI concepts are not limited to Europe only. With the Clean Sky 2 LPA IADP Europe takes the lead to be the first to enter the market with environmentally and economically friendly aircraft.